Manafacturing:

Product Validation & Improvement

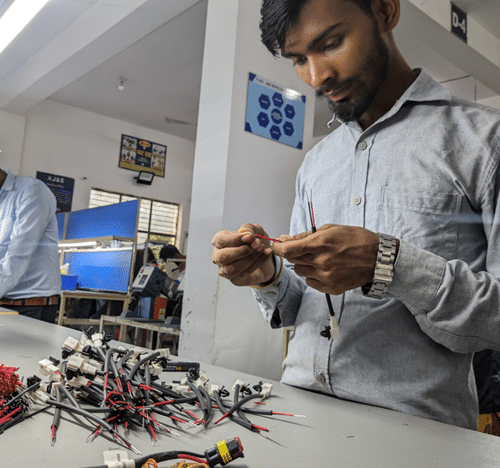

Conducting a thorough 100% end-of-line inspection for the components we supply is essential to ensure we deliver the highest-quality products to our customers.

Validation of Products in Real-Time

- Complete end-of-line circuit inspections to ensure proper fit and electrical continuity

- Thorough end-of-line visual examinations for validating critical parameters

- Incorporation of foolproofing (Poka-Yoke) in circuit inspections

- Utilization of dedicated circuit checking boards customized with various load conditions for individual customers

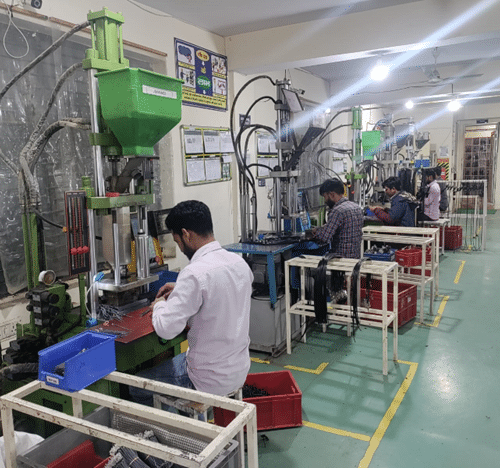

Lean Methodology

- Modularity Efficiency in a compact form

- Single-Minute Exchange of Die (SMED)

- Error-proofing (Poka-Yoke)

- Continuous improvement through Kaizen