Quality

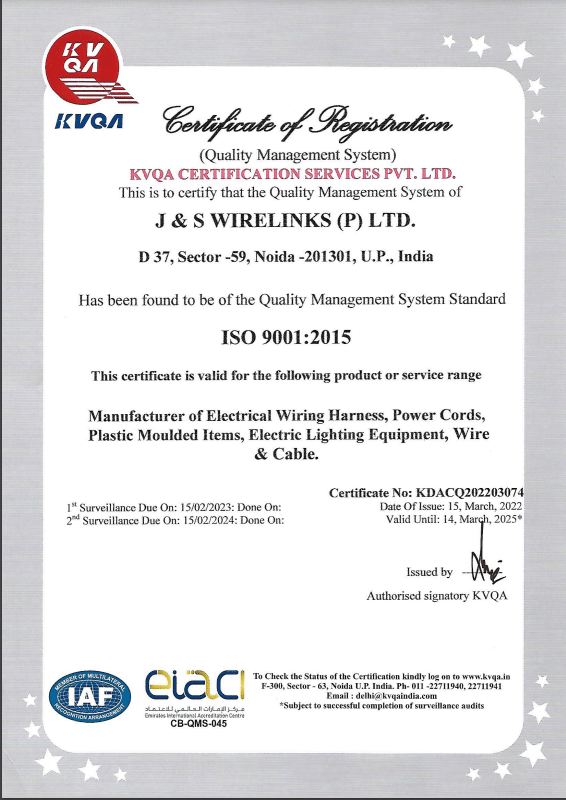

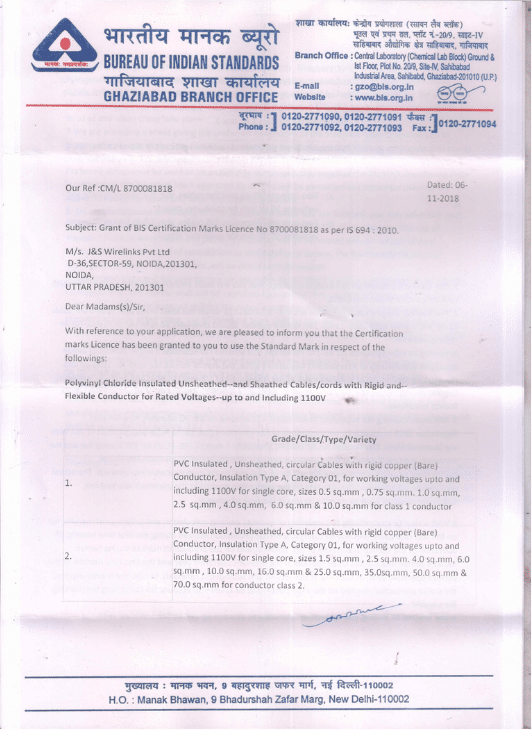

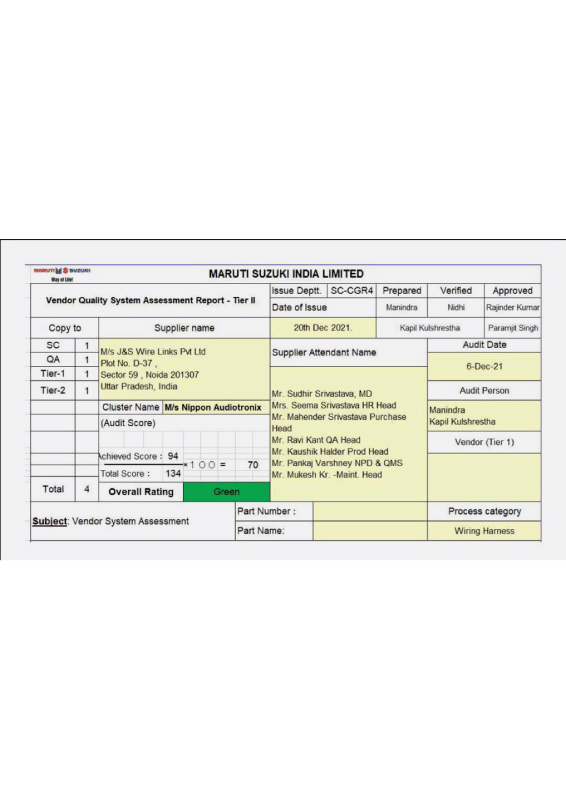

J&S Wirelinks proudly holds ISO 9001:2015, IS:694 & Maruti Suzuki Green certifications, demonstrating our unwavering commitment to maintaining stringent international quality standards. Our rigorous quality control measures ensure that our systems and processes meet the expectations of the most discerning customers.

Our longstanding partnerships with major players in the Indian automotive, Electrical & Electronic industry serve as a testament to our commitment to quality. Our comprehensive quality planning encompasses every stage of production, beginning with supplier identification and upgrades, followed by incoming inspections, in-process audits, calibration activities, and pre-dispatch inspections. These efforts collectively enable the Wiring Harness Division to produce top-tier “Harness” products.

Quality Policy

- We prioritize quality to maintain our competitiveness in the market and deliver cost-effective products to our customers.

- Our commitment to quality is evident in our actions, products, and services for both internal and external customers.

- We foster an environment that encourages all our employees and suppliers to prevent defects and strive for excellence.

Safety Policy

J&S Wirelinks places paramount importance on the safety of its employees. We are dedicated to:

- Implementing comprehensive safety measures throughout our organization in a sustainable manner.

- Identifying, controlling, and reducing factors contributing to safety issues as part of our ongoing improvement efforts.

- Complying with all statutory and regulatory safety requirements

- Fostering awareness and active employee involvement in safety measures.

Environmental Policy

J&S Wirelinks is deeply committed to mitigating the environmental impact of its activities and products. Our environmental policy entails:

- Continuously improving our environmental performance.

- Ensuring compliance with all relevant environmental laws and regulations.

- Promoting environmental awareness among our employees.

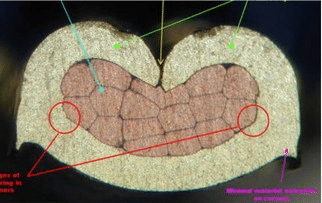

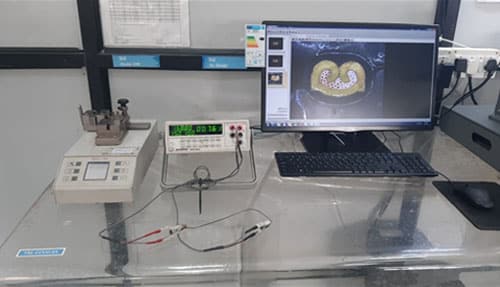

Crimp Validation

- A comprehensive team setup dedicated to Crimp validation

Quality Tools

- Statistical Process Control

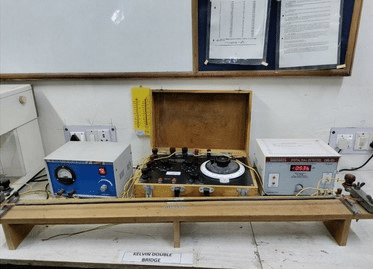

- In-house Product Reliability Testing.

- Utilization of FEA (Finite Element Analysis), QFD (Quality Function Deployment), FMEA (Failure Mode and Effects Analysis), MSA (Measurement System Analysis), and other tools for product and process validation.